Giti Pasand

Industrial Group

Nasser Jannati

Founder of GitiPasand Industrial Group

Giti Pasand Industrial Group, the Mideast largest production complex in the building installation industry, was established in June 1998 through the foundation of polymer, mechanical, and electrical research centers and the establishment of production units in Isfahan. Entrepreneurship and production of high-quality products were the two purposes of founding this complex, both realized in the establishment of 20 production and service units in specialized fields of polymer, construction products (water & sewage), metallurgy, and agriculture. Currently, some 3000 staff cooperate directly with the complex, while so do more than tens of thousands of construction industry experts through indirect ways.

History

Giti Pasand Industrial Group, SGP, the Mideast largest production complex in the building installation industry, established through the foundation of Polymer, Mechanical, and Electrical Research Centers and establishment of 20 Factories.

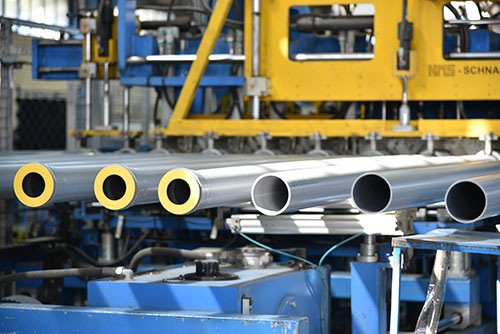

Azin Looleh Sepahan, ALS, producers of PP Single-Layer and Three Layer Pipes. The company now has 24 production lines with an annual capacity of 110 million meters of Pipes and fittings with more than 150 types.

Ati Looleh Sepahan, has been developing PERT/AL/PERT and PEX_b/AL/PEX_b pipes under the brand name NEW PIPE with an annual capacity of 120 million meters of pipes and brass fittings & valves under the brand name of NPA with a variety of more than 500 types.

Novin Ettesal Pardis Gostaresh Company, producer of PP sewage push-fit Pipes and Fittings under the NewFlex brand with products in the sizes of 50 to 160 mm in B, BD and silent types.

In order for responding to the big demands in the market for brass fittings and Five-Layer Pipes and having a balance with the raw material supply, SGP established a production plant for Brass Billets with the name SSE and Polymer Plant with the brand name BP.

Behin Sazan No-Andish Sepahan Factory, known as the second large gypsum board producer in Iran. Its annual capacity of production amounts to 10 million square meters. The factory manufactures its products according to international standard EN520, under the brand name BATIS.

Our Mission

Giti Pasand Industrial Group

To become the leading provider of high- quality pipes, fittings, and installation products in the global market, and the trusted partner in the industry who delivers innovative solutions to meet the diverse needs of its clients while ensuring environmental sustainability and promoting efficient infrastructure development.

Our Vision

Giti Pasand Industrial Group

Changing into the main manufacturer and exporter of pipes, fittings and installation products, becoming the preferred choice for architects, engineers, contractors, and end-users worldwide, and improving lives and communities through creating long-term reliable partnerships with the customers, offering the superior pipe and fitting solutions and constant promotion of the products, processes, and services.

Our Values

Giti Pasand Industrial Group

- Quality: Delivering products that meet or exceed international standards, we ensure our customers they receive products of the highest quality, the best performance and durable solutions they can trust. Continuous improvement of the products should be considered as a must.

- Innovation: To stay at the head of the market, we have no choice but to provide innovative solutions to the clients’ challenge through continuous investing in research and development, and fostering a culture of innovation to deliver cutting- edge products that address emerging industry needs.

- Customer-centricity: Customer long-term satisfaction as our top priority should be placed at the core of our goals. To understand the clients’ unique needs and provide them with tailored solutions, timely supports and exceptional services that may even surpass their expectations, Can guarantee their success and satisfaction.

- Sustainability: We are committed to sustainable manufacturing, operating in an environmentally responsible manner, minimizing our environmental impacts through responsible sourcing, energy- efficient processes, and eco-friendly products design. We prioritize sustainable practices in our manufacturing processes, and actively seek ways to contribute positively to the communities in which we operate.

- Integrity: We must uphold the highest standards of integrity and ethical conduct in all our business dealings. Conducting business ethically, with honesty, transparency, and respect in relationship with the employees, partners and stockholders is never to be abandoned under any circumstances.

- Collaboration: Building strong partnership with suppliers, distributers, and customers, will lead to deep collaborative relationships followed by mutual growth and success.

- transcendence: We foster a culture of Continuous improvement, encouraging our employees to purse excellence in their work. Attempt to operational excellence in all aspects of our business, from production and logistics to customer service and innovation is the very principle helps us to exceed beyond the expectations consistently.

We embrace new ideas, encourage collaboration, and empower our teams to identify opportunities for growth and development. By aligning our operations with these mission, vision and values, we strive to be a leader in the industry and a trusted partner for our clients.